All Blogs, Priming and Protecting

How to Choose a Protective Paint

You’d think choosing a protective paint topcoat with a good finish, especially for metal or wood should be fairly easy. It’s surprising though, how often you need to know quite specifically what you’re looking for.

We supply many professionals from a wide range of industries, but even the most experienced occasionally needs to ask, which paint is best for certain situations or for a particular substrate.

Having explored primer paints in previous articles (Primers for Wood and Walls and Which Metal Primer to Choose), we’re now adding the finishing touch!

Here is our guide to choosing a paint topcoat or finish coat that provides the desired appearance, but which also offers performance and protection. Specifically, we’re talking about paint for metal and wood.

Do you need a topcoat paint?

How important is the topcoat? Whether it’s wood or metal, if a primer has already been applied, some of the vital protective work has already been achieved. A decent primer performs many essential functions including sealing and protecting the surface and helping the topcoat to adhere more easily.

That’s not to say a top or finish coat is not required; it provides the appearance but also acts as a first line of defence in protecting what’s underneath. It should be durable enough to preserve its looks for some time.

Quality topcoat paints also have sealing properties and provide some resistance to chips or scratches.

More about what to look for in a good paint below, but first another very brief word about primers.

Whether to use a primer or not?

With wooden surfaces, we’d suggest that you always use a primer. If covering a previously painted surface however, you may get away with a light sanding down to help the topcoat stick.

A metal surface too, will usually benefit from the right primer, but if time is at a premium you can paint over a previously painted surface or even bare metal.

Direct-to-metal paints like Hammershield can be used on many types of previously painted or bare metal without a primer. Check that the surface is in reasonable condition; if it’s rusty, applying a rust convertor is a quick solution prior to applying the direct to metal paint.

Where you do use a primer be sure that you choose the right one for your metal. Our blog will help. Another thing to be aware of is that choosing the wrong topcoat could adversely affect the performance of the paint. If the primer or top coat you’ve used is solvent borne, find out which solvent it is based on; solvents vary in strength and strong solvents like xylene, will ‘attack’ weaker solvents such as white spirit. Ask your supplier if you’re unsure.

What to look for in a protective paint for metal and wood

Make a few notes about what you will need from the paint including when and how you’ll be using what you’re painting.

For exterior paints, large areas, or well used spaces, you may need to consider: the drying time of the paint; its water resistance; the colour; the UV stability. If plant or machinery is being painted then durability and heat resistance could be a factor.

A smooth, high gloss finish may also be important in some circumstances. Anti-corrosive and rust inhibiting properties will be crucial in outdoor areas and indoor spaces where moisture is present.

Spraying and thinning paint

Large spaces may require a paint that can be sprayed rather than brushed or rolled. If you intend to spray your topcoat, note:

- Some topcoat paints are not designed to be thinned so are not suitable for spraying

- Some colour pigments are more transparent and will need more coats or a certain type of paint

Always ask when you buy (we always have people on hand that can help here at Palatine)

Protective Paint and Terminology

Here are some of the terms (with explanations) which you may see when choosing a protective paint, or that may help you in your search.

1. High Build

A high build coating will give good coverage, allowing you to paint a relatively thick film and to cover small blemishes in just one or two coats without worrying about running or sagging (sometimes known as ‘curtaining’).

2. Wet Edge and Flow Out

Wet edge refers to the ‘brushability’ (or roller-ability) of the edge of the paint that you’ve already applied while it’s still wet or workable. So a paint with a good wet edge will allow you to brush into the edge of the previously painted parts more easily and without leaving ugly brush marks. Flow out refers to how the paint flows or levels after it’s been applied…it is similar to wet edge.

3. Durability

The term durability is used in different ways and can be a bit vague and all-encompassing. It can refer to the length of time the paint will take to “break down” or the “strength” of the paint in terms of cohesion (the strength of the molecular forces). A paint with poor cohesive properties may show signs of abrasion or will crack with age. Durability often simply refers generally to toughness, scratch resistance etc.

4. Adhesion

Adhesion is the ability of the paint to bond to the surface beneath. Poor adhesion will cause issues including lifting and blistering. Good adhesion is important in paint for metals with their smooth, shiny and non-porous surfaces.

5. Coverage

Coverage refers to amount of paint which should cover a certain area. Usually specified as m² per litre

6. Anti-Corrosive and Rust Inhibiting

When rust isn’t treated it continues to oxidise and corrosion occurs which can damage and weaken the metal surface. Anti corrosive and rust inhibiting paints and primers help to prevent this. There are various ways in which different anti corrosion and rust coatings work. Take a look at the Coatings website for more details.

7. Chemical Resistance

A paint described as chemical resistant may not always be ‘resistant’ to the type of chemicals your surface will come into contact with. These may be harsh cleaning products or chemicals used in factory processes etc. Ask your paint supplier more about the resistance of the product to alkaline and/or acidic chemicals.

8. Opacity

Opacity is the ability of the paint to conceal or completely cover what’s beneath it in terms of colour etc. A paint with good opacity will require fewer coats to completely obscure the colour beneath.

9. Paint Finish

The “finish” of a paint refers to the final look of the paint. Gloss, matt, satin, eggshell are the different paint finishes you can achieve on wood and metal.

- Gloss finish is a glass like, highly reflective

- Satin finish will reflect some of the light but won’t be as glassy

- Eggshell has less sheen than satin but is not as ‘flat’ as matt

- Matt has a ‘flat’ finish, which doesn’t reflect any light and has no sheen.

- Hammer finish has an appearance which looks a bit like hammered metal once dry

10. Drying Time

The “drying time” of a paint speaks for itself really. You may see additional detail such as “touch dry” time and “overcoat” or “recoat” time. Ignoring these times will ruin a paint job (more about this in future blogs)

11. Pot Life

Two pack paints require mixing together to initiate a chemical reaction before use. The pot life of a paint refers to the amount of time from mixing the two parts until the paint is no longer useable. It can vary depending on temperature. Always read the instructions!

12. Wet and Dry Film Thickness

Often a specification in commercial and industrial contract requirements, wet and dry film thicknesses are usually indicated in microns. Here’s what they are and how they’re measured:

Wet Film thickness – This is the measure of the thickness or depth of a coat of paint when wet. The Wet film thickness (WFT) is measured (with special gauge that looks like a small comb) while the coating is applied (when still wet).

Dry Film Thickness – This is a measure of thickness or depth of a coat of paint when dry or cured. Dry film thickness can be measured “destructively” or “non-destructively”. The destructive method involves making a cut into the dry coating, right down to the substrate and then measuring. Non destructive measurements can be made with a digital meter.

Do you need a specific colour paint?

We’ve had many a customer truly grateful for certain shades of yellow and orange that they’ve been unable to source. While most large paint retailers are willing to colour match emulsions to almost any colour, we’ve found this isn’t always the case with high quality metal and wood protective paints. This seems to be especially true for the hard wearing coatings that our own customers need in specific shades.

Another note about paint thinning and colour

Some colour tinting pigments have less opacity than others. Certain orange and yellow tinting pigments used in long life coatings are examples of this. If you normally thin a particular type of paint for spraying, you may find that when you “thin” the same paint in an orange or yellow shade, you will need to apply more coats than when using other colours. So when we ask customers if they’re applying by brush, roller or spray, it’s not because we’re being nosy. It means that we can supply the right paint, depending on shade and application, to give right result.

Checkout some of our protective finish paints:

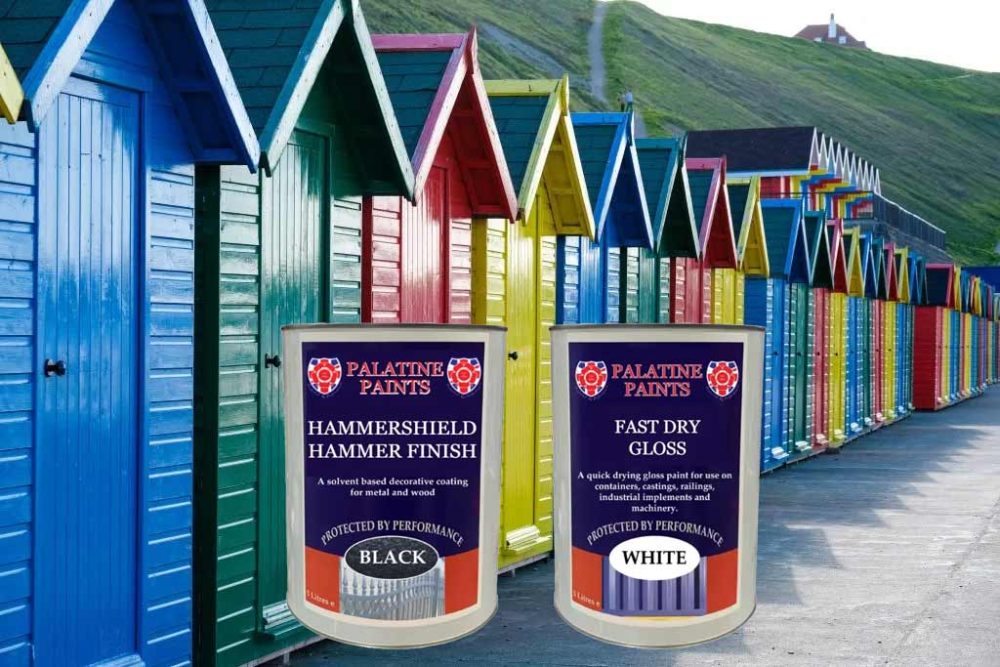

Hammershield – Fast drying direct to metal paint – enables multi coat application in minimal time with no need to prime. This professional product is equivalent to a major well known brand, yet competitively priced and not available on the High Street.

Two Hour Gloss – A high gloss, fast dry enamel, protective and decorative top coat for interior and exterior use. Touch dry in 2 hours with excellent wet edge and flow out.

Fast Dry Gloss and Semi Gloss – High performance, direct to metal coating that provides an excellent gloss (or semi-gloss) finish top coat, ideal for spray application. Suitable for use on steelwork, railings, machinery etc. Touch dry in 20 minutes.

Agricultural and Industrial Gloss – Weatherproof coating that offers a protective & attractive finish. A traditional oxide gloss paint with excellent opacity. For wood, metal and many other surfaces. Can be applied as a direct coating but will perform best when applied over selected Palatine Primers and Undercoats.

Contacting us is easy!

Email: sales@palatinepaints.co.uk

Call Us: 01942 884 122

Contact form: https://www.palatinepaints.co.uk/contact-us

As always, we welcome comments below. We also have our online chat manned each weekday during working hours or call/email us!