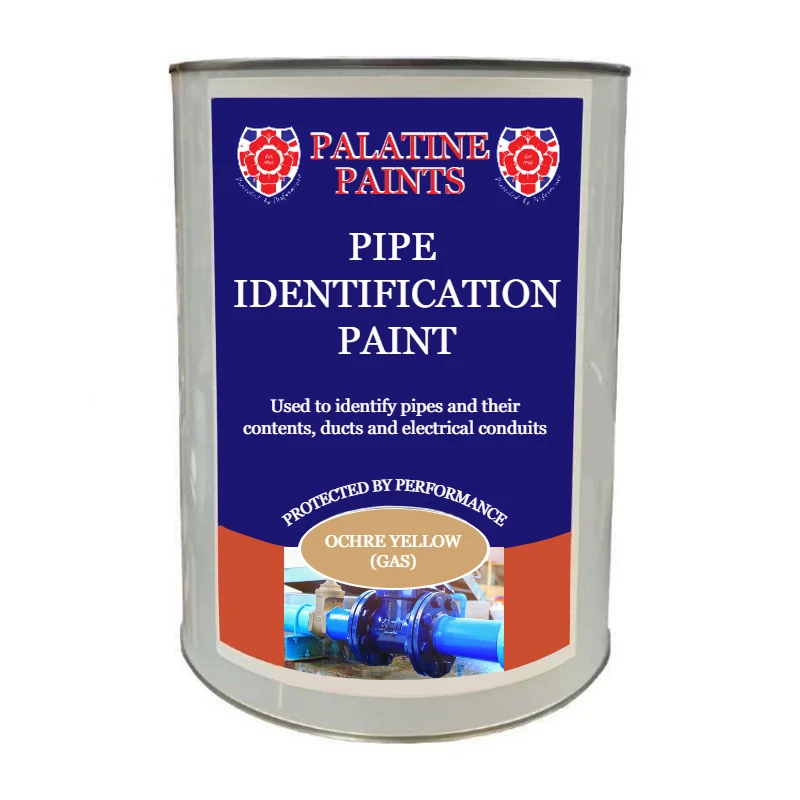

Product Description

Pipeline and Pipework Identification Paint, a fast drying gloss protective coating. A long term durable pipe paint including colours such as yellow ochre gas pipe paint.

Ensure the pipework containing water, gas and oil is identified correctly to avoid hazards

Ensure your building is correctly identified with approved industry standard colour identification. Follow the colour coding to enhance recognition, avoid any accidents and reduce hazards

British Standard 1710, pipe marking standard specifies the colours used for identifying pipes and their contents, ducts and electrical conduit.

Methods of Pipe Marking identification:

- Basic Pipeline Identification Colours

- Code Indicators

- Code colours

- Safety Colours

The standard is essential to building services, waste, water, liquid fuel, gases and refrigeration industries.

British Standard 1710 outlines the requirements for pipelines above and below ground, ventilation ducts and conduits. Also the water supply industry to avoid cross contamination

| BS 1710 Basic Pipeline Identification Colours |

| Pipe Contents |

ID Colour Reference |

BS 4800 |

| Water Pipe |

Green |

12 D 45 |

| Steam Pipe |

Silver Grey |

10 A 03 |

| Oils |

Brown |

06 C 39 |

| Gas Pipe |

Yellow Ochre |

08 C 35 |

| Acids and alkalis |

Violet |

22 C 37 |

| Air |

Light Blue |

20 E 51 |

| Other liquids |

Black |

00 E 53 |

| Electrical services and ventilation ducts |

Orange |

06 E 51 |

| Safety Colours |

BS 4800 |

| Fire Red |

04 E 53 |

| Danger Yellow |

08 E 51 |

| Potable water Blue |

18 E 53 |

Preparation:

Proper surface preparation is essential for the success of any protective coating system. Before you begin ensure the area is free from any dust, oil, grease, old coatings and surface contaminants.

The preparation of steelwork prior to painting generally falls into two main areas; that of degreasing and the removal of rust and scale.

All surfaces to be painted should be clean, dry and free from loose and flaking material, dust, grease and millscale, etc.

Prime bare surfaces with Palatine Anti-Corrosive Metal Primer or Palatine All Purpose Primer / Undercoat in accordance with our recommendations

For non-ferrous metals use Palatine Fast Dry etching primer.

Rub down previously gloss painted surfaces with fine waterproof abrasive paper and rinse thoroughly.

Application:

Best results are obtained in warm (minimum 10°C), dry conditions.

Mix thoroughly for approximately 2 minutes using a drill stirrer. A wooden batten at least 25mm wide is also ideal.

Apply an even coat using a brush, short to medium pile roller on smooth surfaces and a long pile roller on textured surfaces

For spray application by either airless or conventional spray a dilution ration of no more than 10% is recommended with Palatine White Spirit by volume applying thin coats allowing each one to dry before applying subsequent coats.

Once dried, a second coat can be applied at full strength. This will prolong the life and performance of the coating.

Thinning and Cleaning: Use Palatine White Spirit.

If using more than one batch of the same colour, intermix before use

Please note: The colours on the product listings are only given as a guide. This is due to the fact that every computer monitor has a different capability to display colours. In addition, everyone sees these colours differently. Sample pots are available to order upon request. Always carry out a test patch (approximately 100x100mm) before full application to ensure compatibility with previous coatings and the substrate, and to ensure the colour achieved meets your requirements. Failure to do so will result in a product refund claim not being accepted.

Reviews

There are no reviews yet.